Meeting Fluctuating Power Needs with Diesel Generators

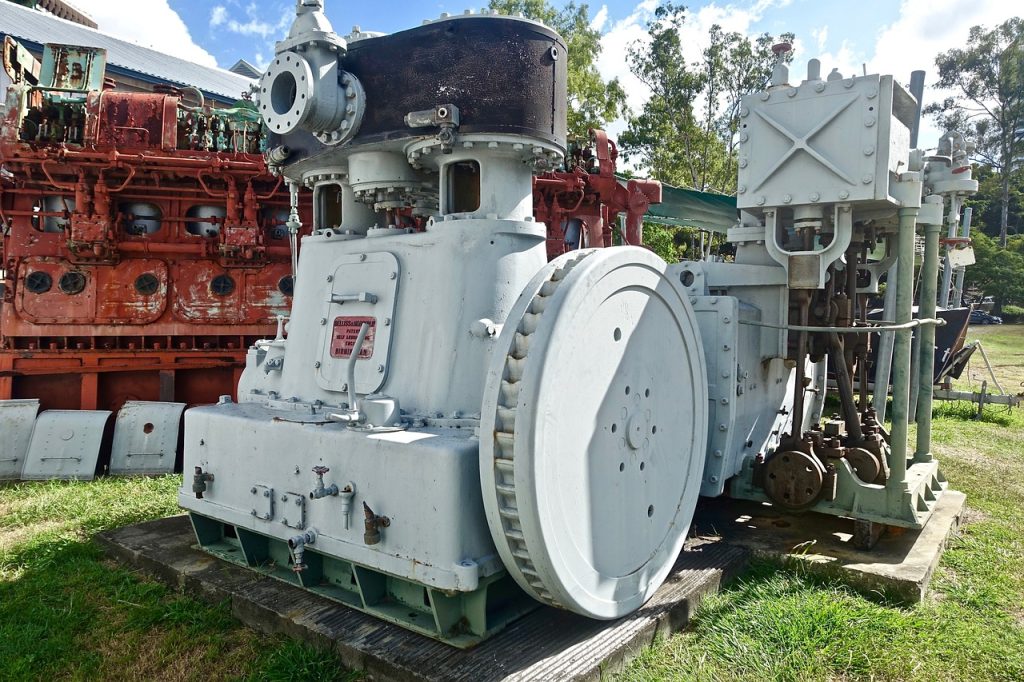

Introduction In today's modern world, reliable and consistent power supply is crucial for homes, businesses, industries, and infrastructure. However, fluctuating power needs due to various factors such as weather conditions, peak demand periods, or remote locations can pose challenges to maintaining a stable electricity supply. In such situations, diesel generators play a vital role in providing backup power and ensuring uninterrupted operations. This article explores the role of diesel generators in meeting fluctuating power needs, their benefits, applications, and considerations for choosing the right generator for specific requirements. Understanding Diesel Generators Diesel generators are a type of backup power system that utilizes a diesel engine to generate electricity. They are commonly used in situations where a reliable and continuous power supply is required, such as during power outages, in remote areas without access to the grid, or in industries with critical power needs. Diesel generators are known for their efficiency, reliability, and durability, making them a popular choice for a wide range of applications. How Diesel Generators Work Diesel generators operate on the principle of converting diesel fuel into mechanical energy through the combustion process in the engine. The mechanical energy is then converted into electrical energy through an alternator or generator. The electricity generated can be used to power various electrical devices, equipment, or an entire facility depending on the capacity of the generator. Key Components of a Diesel Generator System A typical diesel generator system consists of several key components that work together to ensure the efficient generation and distribution of electricity. These components include: 1. Diesel Engine: The diesel engine is the primary component of the generator that burns diesel fuel to produce mechanical energy. It is responsible for driving the generator and converting fuel into power. 2. Alternator or Generator: The alternator or generator is the component that converts the mechanical energy from the engine into electrical energy. It generates the voltage and current required to power electrical loads. 3. Fuel System: The fuel system supplies diesel fuel to the engine for combustion. It includes a fuel tank, fuel pump, fuel filter, and fuel injection system to ensure a constant and clean fuel supply. 4. Cooling System: The cooling system regulates the temperature of the engine to prevent overheating and ensure optimal performance. It typically includes a radiator, coolant, and fan to dissipate excess heat. 5. Control Panel: The control panel is the interface that allows users to monitor and control the operation of the generator. It displays key parameters such as voltage, current, frequency, and engine status, and enables users to start, stop, and configure the generator as needed. Benefits of Diesel Generators for Fluctuating Power Needs Diesel generators offer several benefits that make them well-suited for meeting fluctuating power needs in various applications. Some of the key benefits include: 1. Reliability: Diesel generators are known for their reliability and durability, making them ideal for providing backup power during emergencies or power outages. They can start quickly and operate continuously for extended periods, ensuring uninterrupted power supply when needed. 2. Fuel Efficiency: Diesel engines are more fuel-efficient compared to gasoline engines, providing higher power output with lower fuel consumption. This makes diesel generators a cost-effective option for long-term power generation. 3. Scalability: Diesel generators come in a wide range of sizes and power capacities, allowing users to choose a generator that matches their specific power requirements. They can be easily scaled up or down to accommodate fluctuating power needs. 4. Quick Start-Up: Diesel generators can start and reach full power output within seconds, making them suitable for applications where immediate power is required. This quick start-up time is crucial in emergency situations or critical operations. 5. Low Maintenance: Diesel generators are relatively low maintenance compared to other types of generators. They have fewer moving parts, require less frequent servicing, and have longer service intervals, reducing overall maintenance costs. Applications of Diesel Generators for Fluctuating Power Needs Diesel generators find wide-ranging applications in various industries and sectors where fluctuating power needs must be met efficiently and reliably. Some common applications of diesel generators include: 1. Standby Power: Diesel generators are often used as standby power sources in commercial buildings, hospitals, data centers, and other critical facilities to ensure uninterrupted power supply during outages or emergencies. 2. Remote Locations: Diesel generators are essential in remote locations where access to the grid is limited or unreliable. They provide a reliable source of power for off-grid communities, construction sites, mining operations, and telecommunications infrastructure. 3. Agriculture: Diesel generators are used in agriculture for powering irrigation systems, farm equipment, and processing facilities. They help farmers maintain operations and ensure productivity even in areas with unreliable grid power. 4. Construction: Diesel generators are commonly used in the construction industry to power tools, equipment, and temporary facilities at job sites. They provide a mobile and versatile power solution for construction projects of all sizes. 5. Events and Entertainment: Diesel generators are utilized in events, concerts, festivals, and outdoor gatherings to power lighting, sound systems, and other electrical equipment. They offer a reliable power source for temporary installations in remote or off-grid locations. Considerations for Choosing a Diesel Generator When selecting a diesel generator for fluctuating power needs, several factors should be considered to ensure that the generator meets specific requirements and provides reliable power supply. Some key considerations include: 1. Power Capacity: Determine the power capacity required based on the total electrical load that the generator will be required to support. Consider https://www.lkpowerplant.com/product/quick-delivery-emergency-standby-power-400kw-silent-type-diesel-generator-set-for-peru/ and the peak power requirements to ensure that the generator can handle fluctuating loads. 2. Fuel Efficiency: Evaluate the fuel efficiency of the generator to determine the operating costs and fuel consumption over time. Choose a generator with a high fuel efficiency rating to minimize fuel expenses and optimize operation. 3. Emissions Compliance: Ensure that the diesel generator meets environmental regulations and emissions standards to reduce the impact on air quality and comply with local regulations. Look for generators with advanced emission control technologies for cleaner operation. 4. Operating Conditions: Consider the operating conditions where the generator will be used, such as temperature, humidity, altitude, and ventilation requirements. Choose a generator that is designed to withstand the specific environmental conditions of the installation site. 5. Noise Levels: Evaluate the noise levels produced by the generator during operation to minimize disturbances to nearby residents, workers, or sensitive equipment. Select a generator with sound-attenuated enclosures or mufflers for quieter operation. 6. Maintenance Requirements: Assess the maintenance requirements of the generator, including service intervals, spare parts availability, and technical support. Choose a generator with a reliable maintenance schedule and easy access to service providers for routine maintenance and repairs.  Conclusion Diesel generators play a crucial role in meeting fluctuating power needs in various applications, providing a reliable and efficient power source for critical operations, emergency backup, remote locations, and temporary installations. With their reliability, fuel efficiency, scalability, and quick start-up capabilities, diesel generators are well-suited for ensuring uninterrupted power supply in challenging environments and situations. By considering key factors such as power capacity, fuel efficiency, emissions compliance, operating conditions, noise levels, and maintenance requirements, users can select the right diesel generator to meet their specific power needs effectively. Diesel generators continue to be a valuable asset for addressing fluctuating power demands and maintaining operational continuity in a dynamic and ever-changing energy landscape.

Conclusion Diesel generators play a crucial role in meeting fluctuating power needs in various applications, providing a reliable and efficient power source for critical operations, emergency backup, remote locations, and temporary installations. With their reliability, fuel efficiency, scalability, and quick start-up capabilities, diesel generators are well-suited for ensuring uninterrupted power supply in challenging environments and situations. By considering key factors such as power capacity, fuel efficiency, emissions compliance, operating conditions, noise levels, and maintenance requirements, users can select the right diesel generator to meet their specific power needs effectively. Diesel generators continue to be a valuable asset for addressing fluctuating power demands and maintaining operational continuity in a dynamic and ever-changing energy landscape.